The S&OP is a tool that was created in the 70s with the purpose of operations planning mainly for manufacturing environments Since then, the planning tool has expanded its scope to other departments and other industries But, let see what is the S&OP definition from the APICS Dictionary 15th editionOperations Planning Practice His global consulting experience – which spans more than 100 clients across a variety of industries – is focused on supply chain design and analysis, inventory strategyOperations Planning (S&OP) Online Course Spring 21 Dates to be Determined Sales &

Educational Videos Ascm 19

S&op definition apics

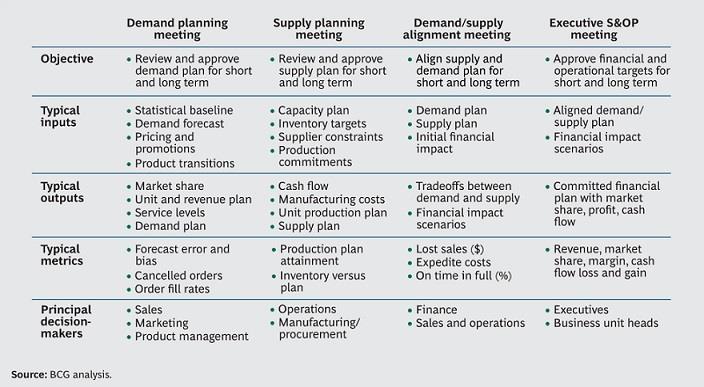

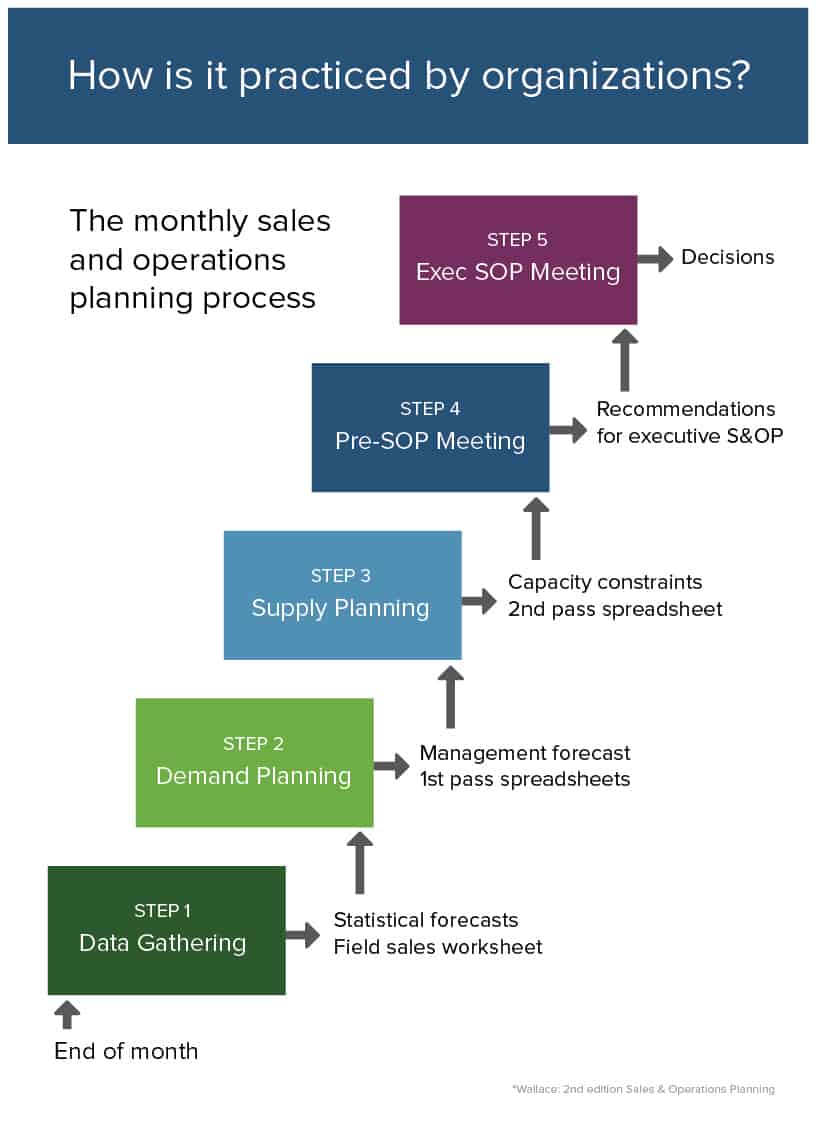

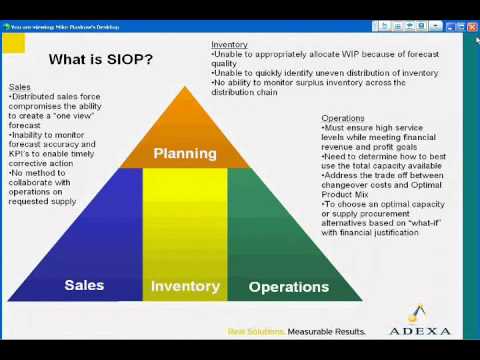

S&op definition apics-Sales and operations planning docx Jaipur National University MBA OM 101Alternatives, sends findings to executive S&OP Executive S&OP team Makes decisions on critical issues, authorizes spending for production, reviews financial plan to business performance "Who are the owners of the S&OP process" Without effective process governance S&OP process planning, control, execution, and improvement will fail

What Is Supply Chain Management Scm

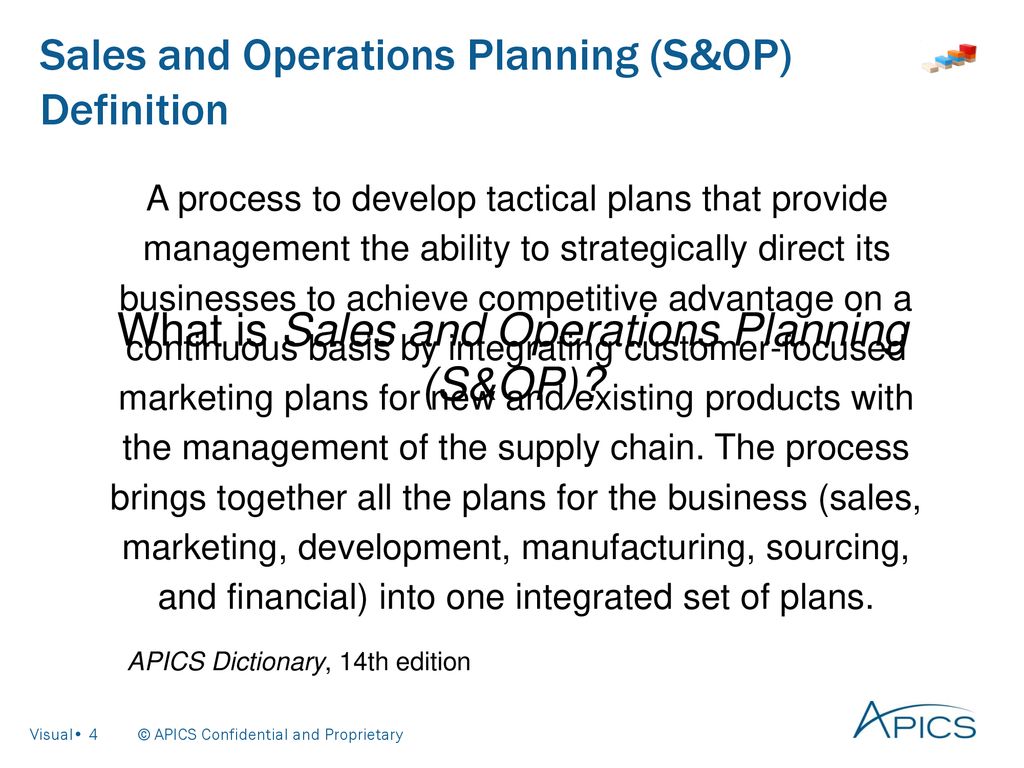

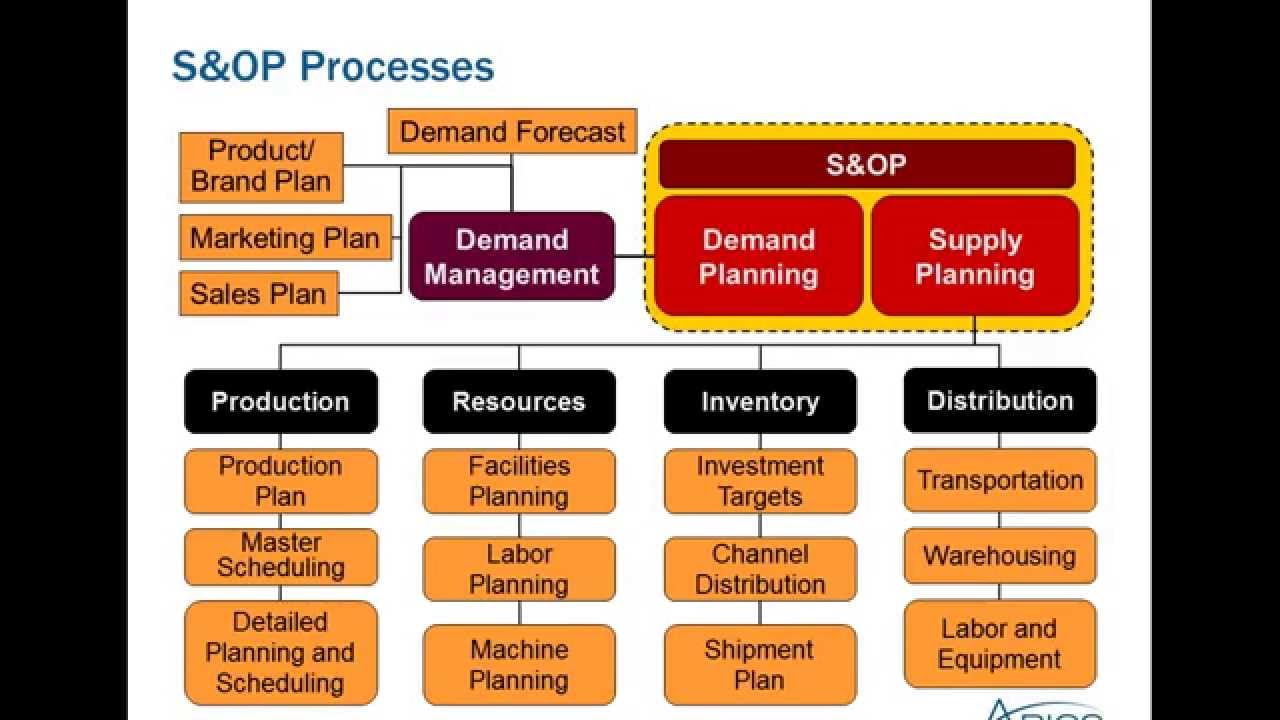

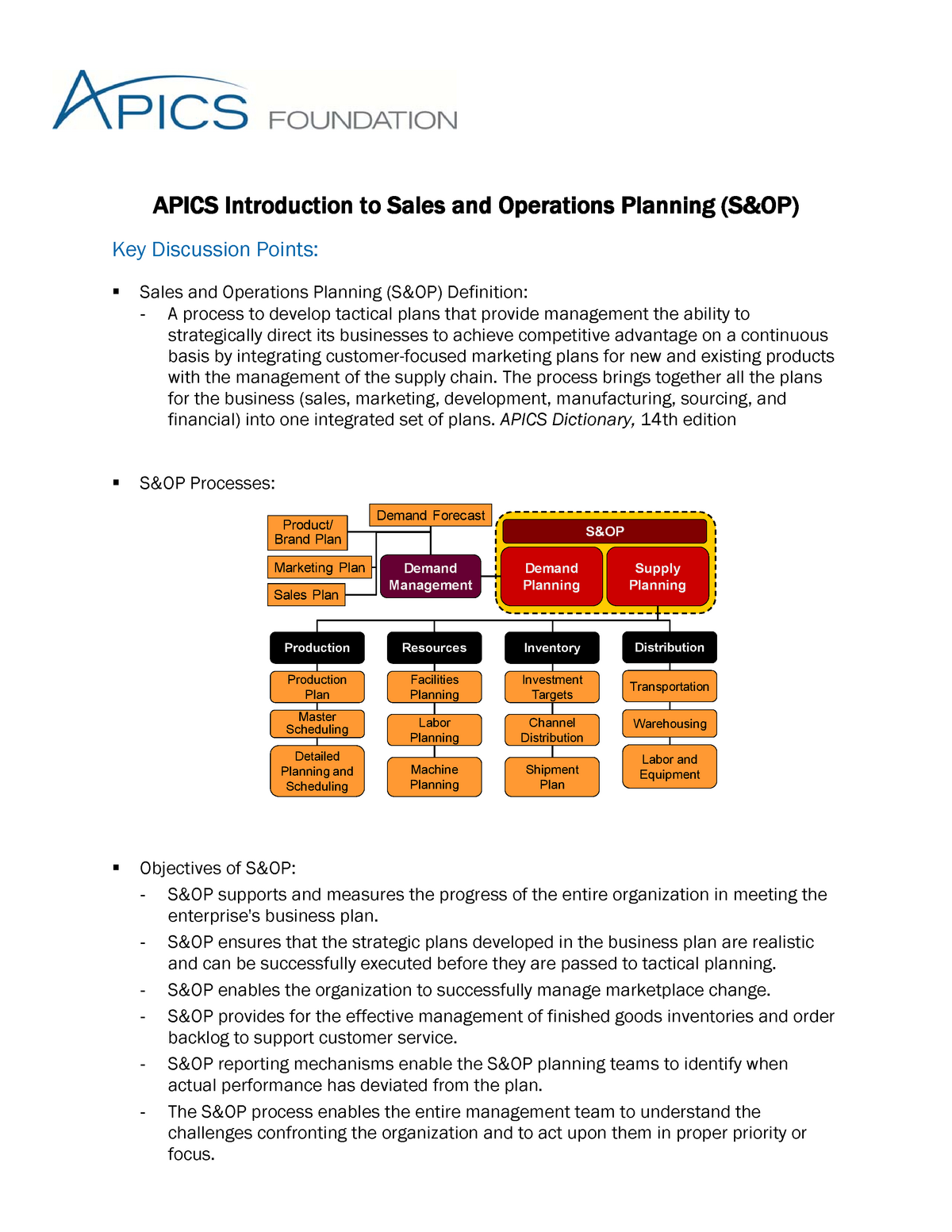

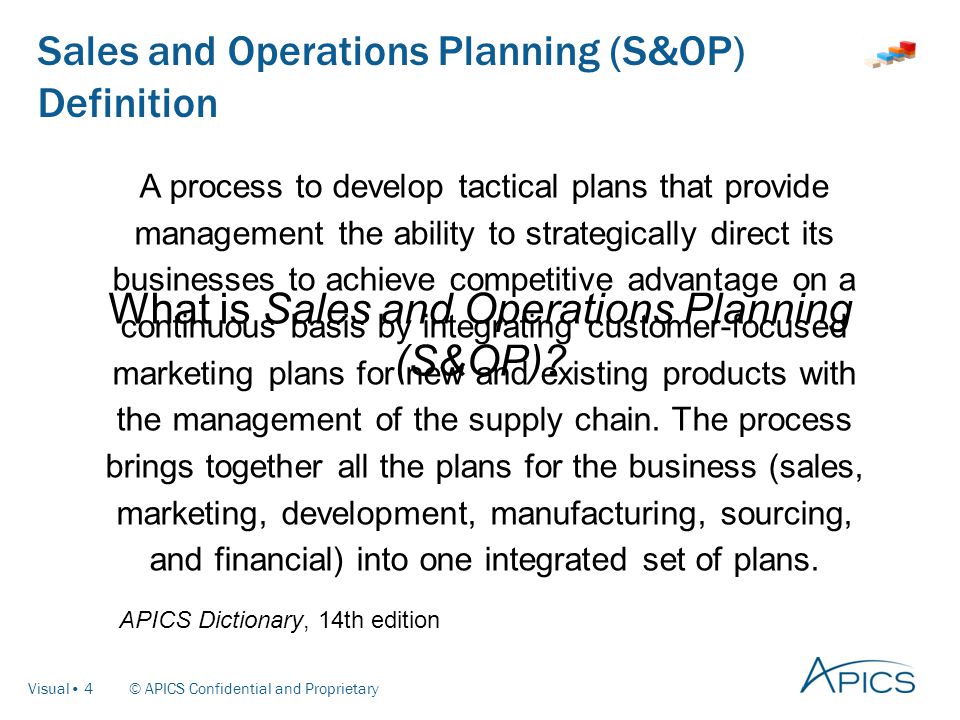

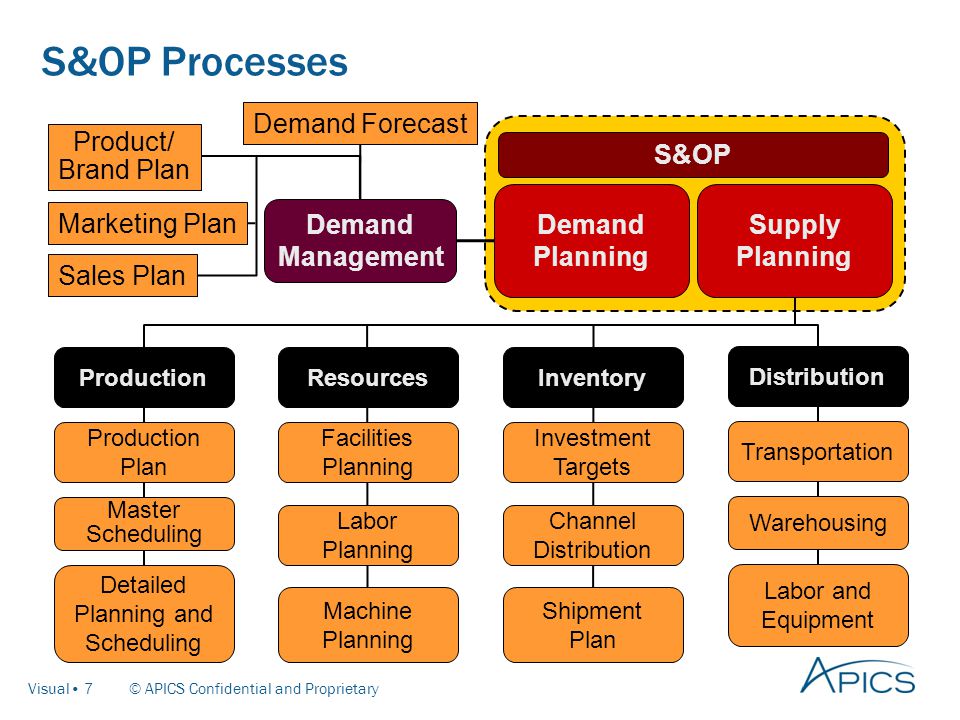

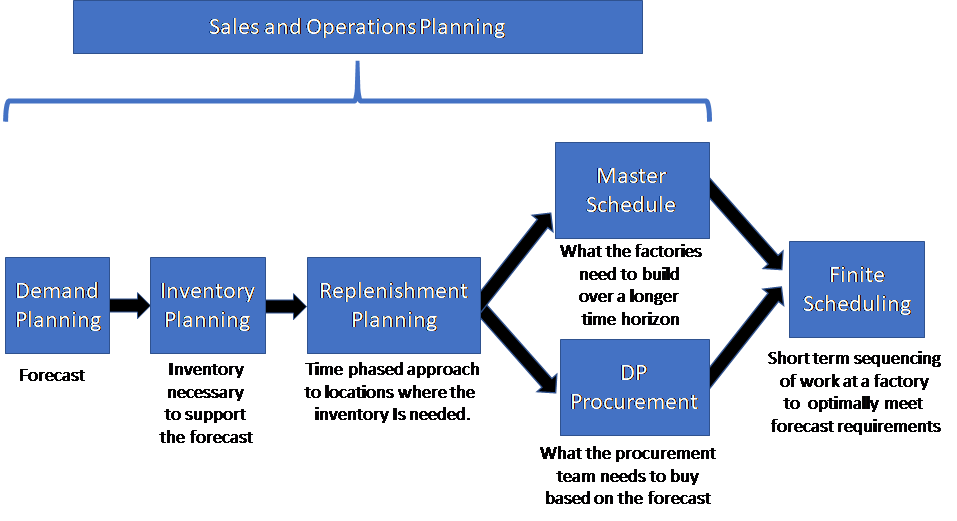

Sales and Operations Planning (S&OP) Sales and operations planning (S&OP) is a business management process where leadership and executive teams meet to ensure each business function is aligned to balance supply and demand S&OP requires crossorganizational collaboration to create detailed forecasts for predicted salesF Sales and Operations Planning (S&OP) Definition A process to develop tactical plans that provide management the ability to strategically direct its businesses to achieve competitive advantage on a What is Sales continuous basis byandASCM is continuing to provide the industryleading APICS certifications and training youʼve come to trust Weʼre also expanding to deliver endtoend professional development and education offerings through our global network of thought leadership partnerships and alliances With ASCM's wideranging programs and services, we help

The definition of S&OP in the APICS Dictionary, 13th Edition A process to develop tactical plans that provide management the ability to strategically direct its businesses to achieve competitive advantage on a continuous basis by integrating customerfocused marketing plansS&OP, it is difficult to fully understand the impact of sourcing, inventory, postponement, and other pivotal business strategies (The concept and impact of metrics on the S&OP process will be discussed in more detail later in this paper) S&OP is a process that by nature unites allView Amit Soni's profile on LinkedIn, the world's largest professional community Amit has 6 jobs listed on their profile See the complete profile on LinkedIn and discover Amit's connections and jobs at similar companies

Presents APICS Sales &Service levels – this metric will measure how well you satisfy your customers from ontime delivery, complete orders, etc This is sometimes measured by the "perfect order" Lead time – the shorter your lead times vs competition, the more likely you'll be able to grow sales, assuming all else is equal Margins – how well you havePivotal role in the definition of the overall IBP solution and architecture and integration with multiple legacy systems Implementation of custom solution for shelflife planning within IBP Project manager and IBP expert in a project dedicated Multinational pharma project, implementation of SAP IBP for S&OP

Apics Trends Shaping Evolution Of S Op Integrated Business Plannin

Apics Introduction To Sales And Operations Planning S Op Ppt Download

A big theme at APICS involved exhorting supply chain managers to communicate with sales and operations (S&OP) teams and view the two departments collectively — supply chain and S&OP — as a coordinated unit, in order to make supply chains more efficient and intentional Don Sheldon, the vice president of education for the APICS Southern Tier, calls S&OP theAn S&OP plan is only as solid as the components that go into it One of the most important is the demand plan, which contains projected sales forecasts and other demandrelated data In order for the demand plan to capture the information that all consumers of the S&OP will need, those responsible for creating the demand plan would do well toAt APICS, we know that there's more to supply chain than management, more to performance than process and more to people than position descriptions We're known for our ability to develop supply chain talent and elevate endtoend supply chain performance Nobody does this better than we do From education and certification to benchmarking and best practices, APICS sets the

A Pragmatic Approach To Sales And Operations Planning Apics

Ppt Apics Introduction To Sales And Operations Planning S Op Powerpoint Presentation Id

Definition APICS defines S&OP as the function of setting the overall level of manufacturing output (production plan) and other activities to best satisfy the current planned levels of sales (sales plan and/or forecasts), while meeting general business objectives of profitability, productivity, competitive customer lead times, etc, asASCM Dayton Chapter, Formerly Apics Dayton Chapter S&OP – Sales and Operations Planning, Forecasting, Demand Management and Supply Planning Product Definition at GE AviationDefinition 1Throughput The throughput volume of a system during a specified time period is constrained by the bottleneck (drum that controls the throughput of the entire system 2Rope The rope communicates the schedule of raw material releases to the gateway operation;This establishes a flow of materials to the bottleneck that ensures the

Apics Monadnock Chapter Webinar Fundamentals Of S Op By Quinn Golden

Apics Introduction To S Op Pdm Inventory Accountability

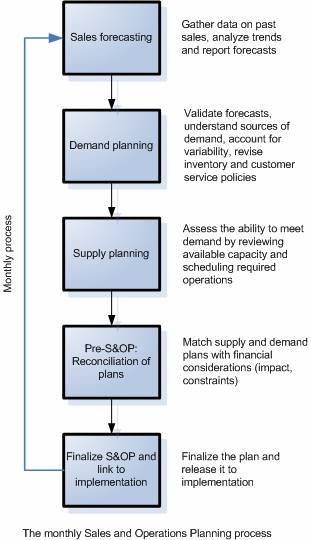

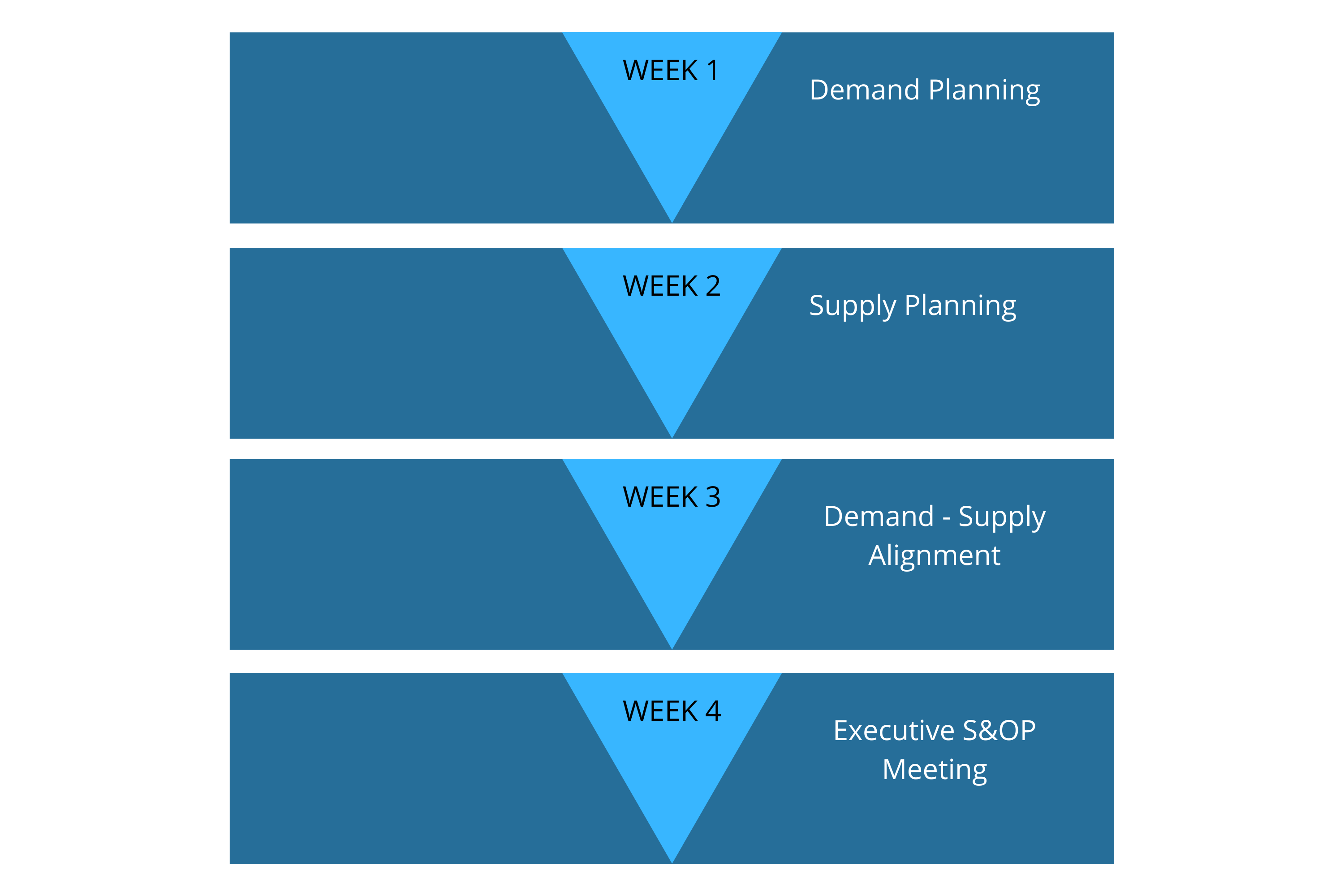

An S&OP process successful In Figure 1, there is a list of a dozen factors that can help lead to operating an S&OP process that maintains exceptional supply chain operational performance over time These factors are detailed below 1 Ongoing, Routine S&OP Meetings A key aspect of an S&OP process is that it is comprised of routine meetingsS&OP has existed in principle going back to the 1980s (Grimson &S&OE smooths the daytoday volatility for more controlled operations In Set Up Sales and Operations Execution Process to Support the S&OP Cycle Pukkila explains, "Because of the shortterm view to the supply chain and manufacturing management, the daytoday noise and volatility seem worse than it may be The result in many companies in this situation is that they

Ppt Apics Introduction To Sales And Operations Planning S Op Powerpoint Presentation Id

Proposal Of A Model For Sales And Operations Planning S Op Maturity Evaluation

An effective S&OP process helps the management of any business in business decisions, strategies, and control over the business to make it successful APICS has made a research on S&OP on various aspects like reasons for underperformance in S&OP, strategy to manage complexity, variability in demand and sales forecast and major shortcomings of S&OPOperations Planning (S&OP) Online Course Tuesdays, September 14, 21, 28 and 500pm – 700pm MDT Expand your knowledge and understanding with a broad range of topics in Sales &Here's how the American Production and Inventory Control Society (APICS) defines S&OP "The function of setting the overall level of manufacturing output (production plan) and other activities to best satisfy the current planned levels of sales (sales plan and/or forecasts), while meeting general business objectives of profitability

Apics Principles Of Sales Operation Planning S Op Knowerx Top Level Partners Of Apics

What Is S Op How S Op Works Demand Planning Com

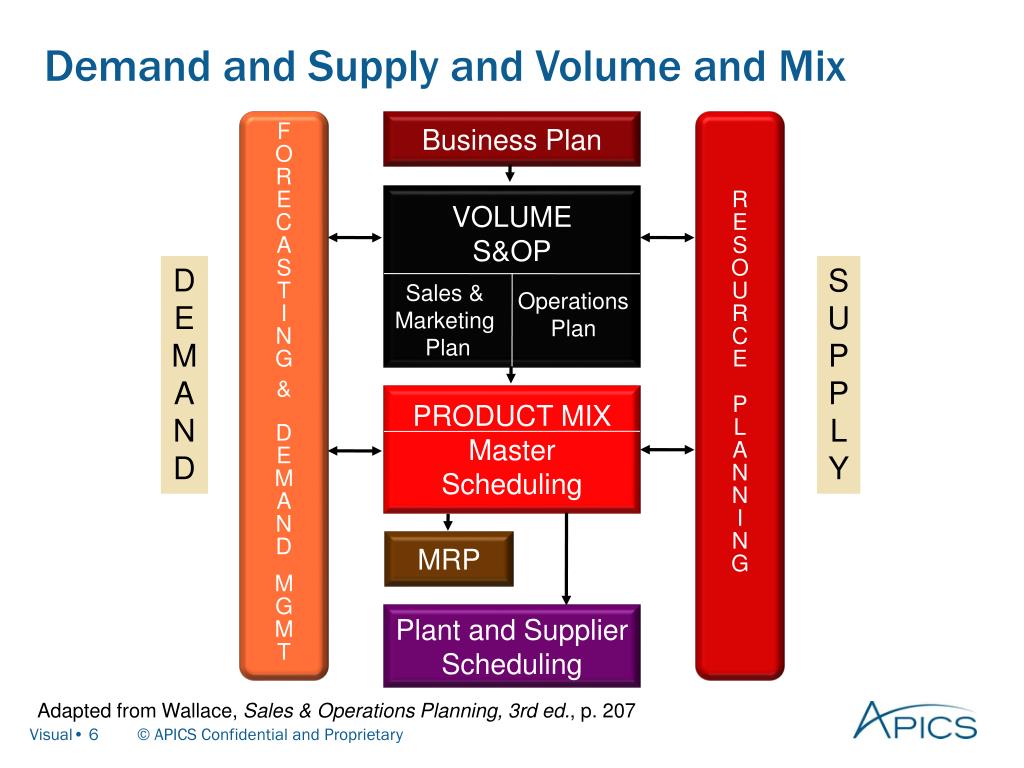

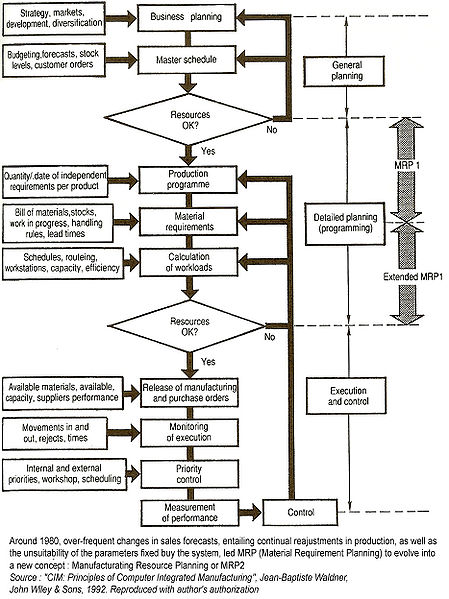

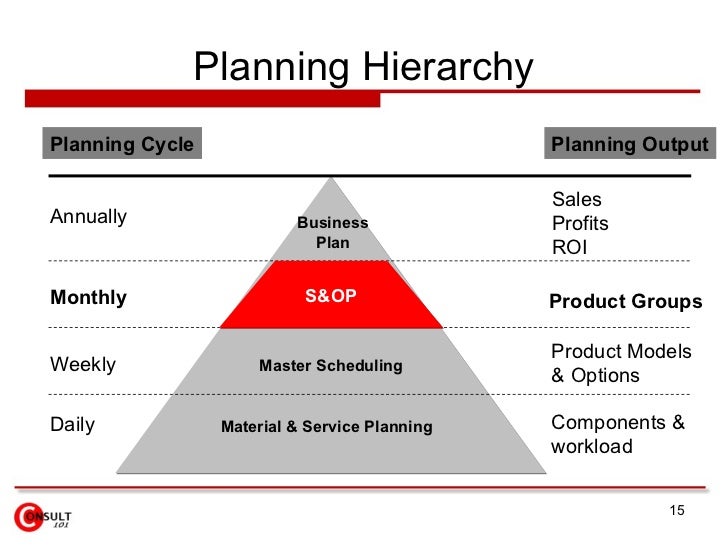

Start studying APICS Module 2 Session 5 S&OP Learn vocabulary, terms, and more with flashcards, games, and other study toolsAPICS' most recent definition of S&OP resembles the Oliver Wight Integrated Business Planning model very closely It demonstrates the evolution not only of APICS, but also of S&OP All of the APICS and S&OP developments started before the emergence of a new discipline, SUPPLY CHAIN MANAGEMENTMaster Scheduler's task is to balance demand and supply at the mix level It's concern with which individual products to run first, second, third and which customer orders will ship when These words are saying that SIOP and Master Scheduling are not the same thing They're different tools for different purposes

Boldly Overhauling A Broken S Op Process Supply Chain 24 7

1

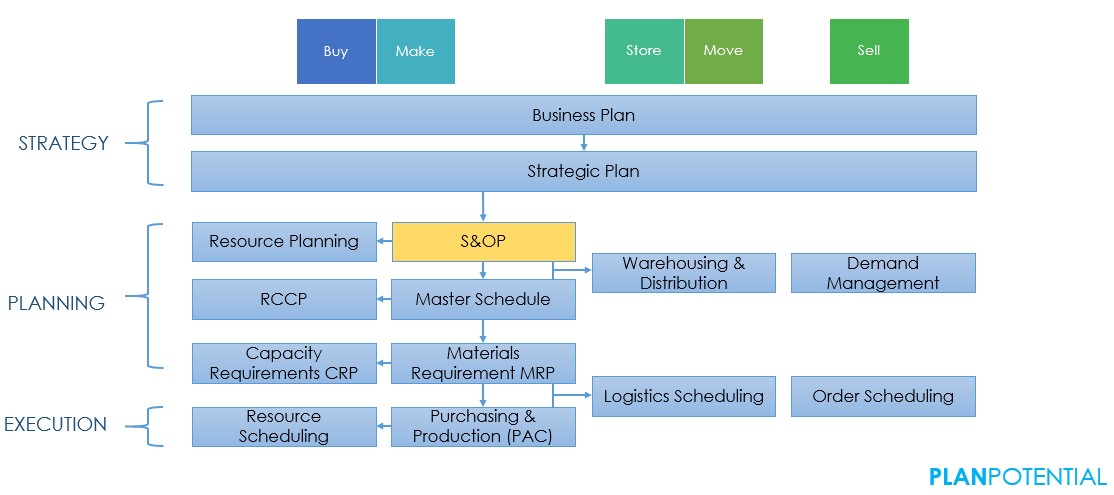

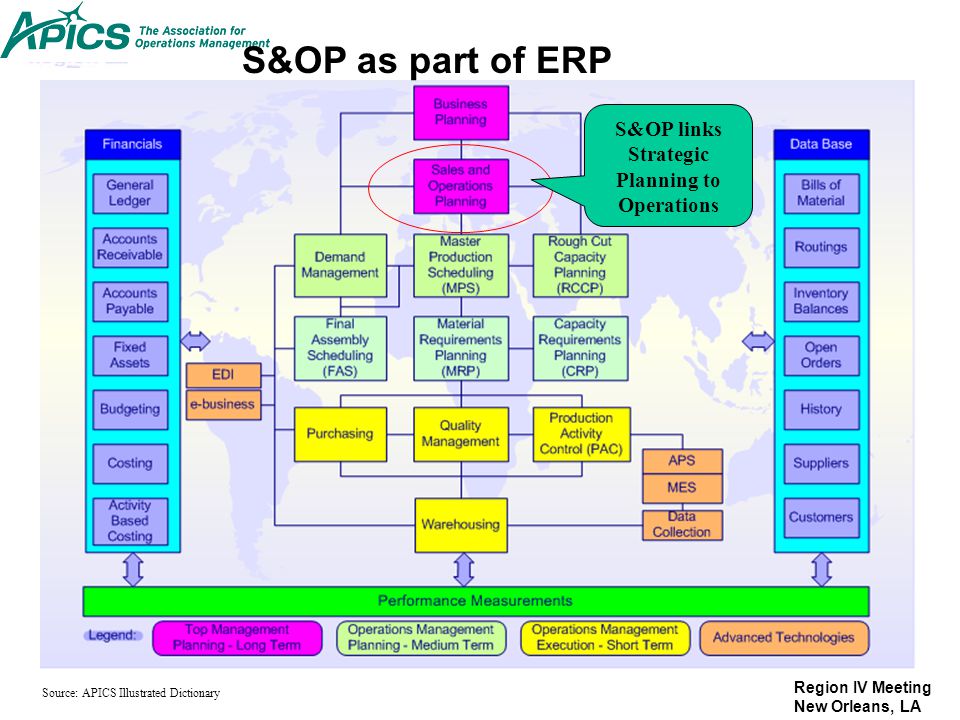

S&OP was introduced in the late 1970s by the business consultant Oliver Wight The process started to evolve as organizations started to share S&OP experiences in organizations such as APICS and, in 1987, the S&OP process was defined as a business process with the goal of balancing supply and demand 7Operations Planning meetings are efficient?The APICS Dictionary, 16th edition, defines manufacturing planning and control system (MPC) in part as follows Exhibit 117 shows how the components of MPC discussed in the definition interrelate Exhibit 117 Manufacturing Planning and Control phases will also be accounted for at the higher S&OP or production plan level (the

Nanopdf Com

Workshops Solutions Business Consultant

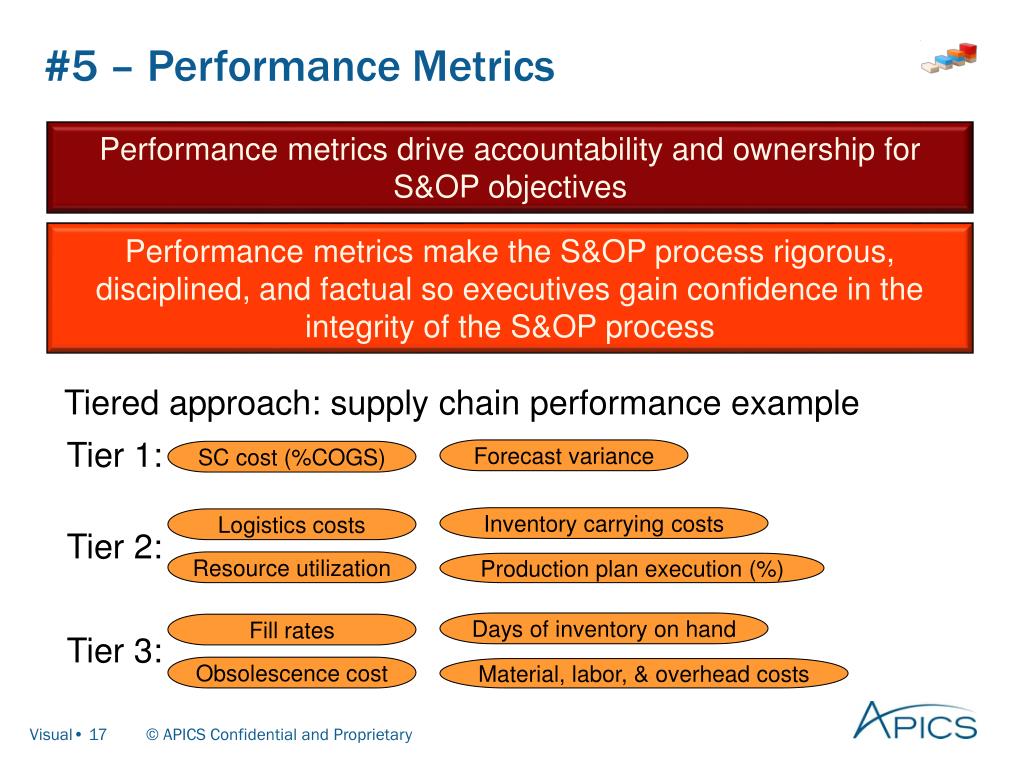

Operations Planning (S&OP) is about balancing the supply chain triangle of service, cash and cost, and thus optimizing the shareholder value by maximizing the Return On Capital Employed (ROCE) But which metrics should you apply in order to ensure your Sales &"walk the talk" Achieving process compliance Identifying S&OP Champion or expert to lead implementation Clear definition and acceptance of roles and responsibilities, including defining specific objectives in employee appraisals Establishing S&OP meetings as the business prioritySimple Methodology for MAPE This is a simple but Intuitive Method to calculate MAPE Add all the absolute errors across all items, call this A;

Ascm Org

Ascm Org

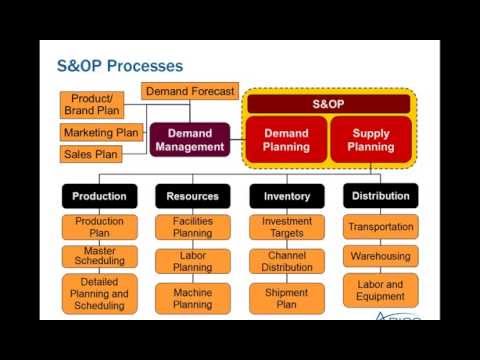

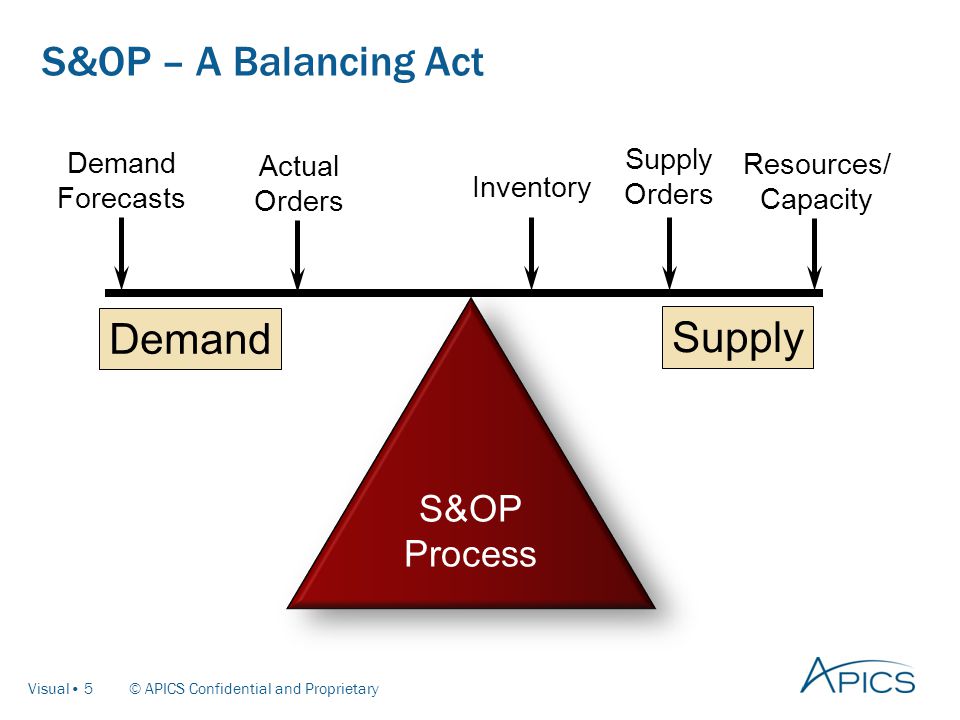

Operations Planning Overview and Definition, Organizations with Separate and Integrated Business Plans, S&OP Balancing Act, In the MPC System, Inputs and Outputs, Planning ProcessWhat is Sales &Pyke, 07) and emerged out of what was known as materials requirements planning A formal definition of S&OP from APICS, a leading professional association for supply chain and operations management is as follows

Sales And Operations Planning S Op Back And Better Than Ever

S Op The Evolving Supply Chain Lifeline Supplychainomics

S&OP Challenges Challenges Senior leadership support &API S' most recent definition of S&OP resembles the Oliver Wight Integrated usiness Planning model very closely It demonstrates the evolution not only of APICS, but also of S&OP All of the APICS and S&OP developments started before the emergence of a new discipline, SUPPLY CHAINMany supply chain organizations determine their

The S Op And The 3 Different Levels Of General Planning Based On Apics Download Scientific Diagram

Blogs

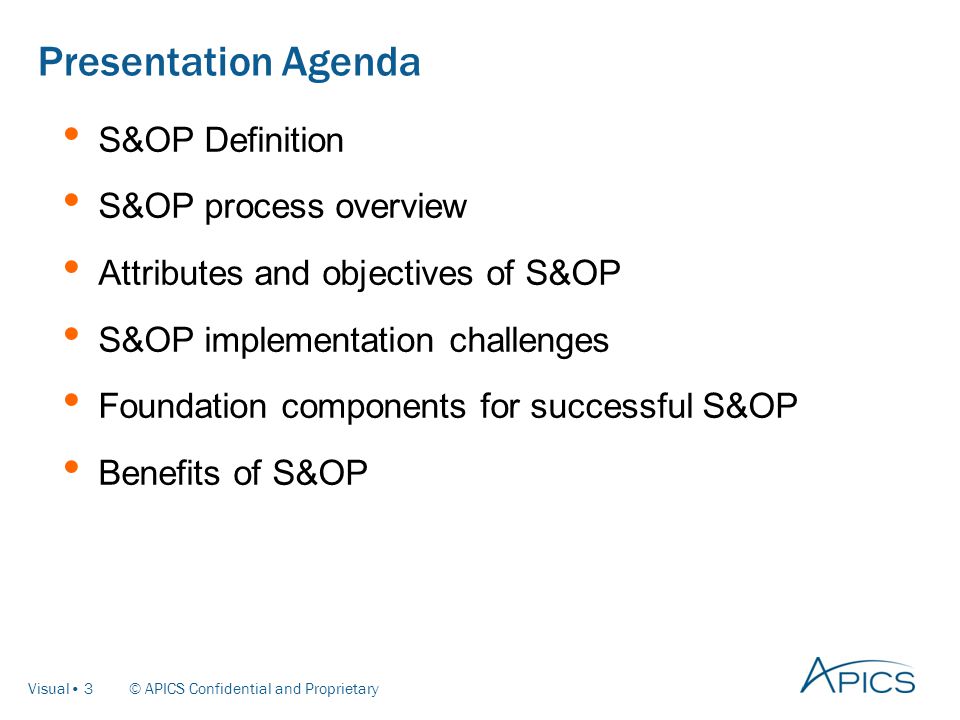

The APICS Principles of S&OP seminar provides managers and planners a comprehensive review of the principles and functions of S&OP Attendees will participate in exercises and discussions on the elements of data collection, demand and supply planning, and conducting the pre and executive S&OP meetings The presenter will lead attendees throughAPICS S&OP PERFORMANCE REPORT 9 Good, Better, Best Knowing the perspectives and needs of your S&OP professionals and optimizing that knowledge across the team, can lead to highperformance S&OP A highperformance team not only serves the process of balancing supply andVice President, S&OP Practice Chainalytics Jeff is a cofounder of Chainalytics and Vice President of the Sales &

Using Six Sigma To Maximize Supply Chain Efficiency Dsj Global

Sales And Operations Planning The How To Handbook Wallace Thomas F Stahl Robert A Amazon Com Books

Therefore S&OP is an increasingly important element of strategic and operational corporate management Therefore, BearingPoint proposes a valueoriented approach to evaluate and improve current S&OP processes to be prepared for upcoming challengesUnderstand the impact that S&OP output has on the distribution planThe APICS Principles of S&OP seminar provides managers and planners a comprehensive review of the principles and functions of S&OP Attendees will participate in exercises and discussions on the elements of data collection, demand and supply planning, and conducting the pre andPropos 10 years of Experience as Project Manager with a demonstrated history of working in the food production industry Recent development in Supply Chain field of expertise (S&OP process) APICS CPIM certification Transversal and multicultural management Recognized for dedication and interpersonal skills Fluent English

Sales And Operations Planning Pdfcoffee Com

S Op Process In 21 Master Schedule Process Management

Learn from an APICSrecognized instructor in a class of your peers Choose from our network of over 300 APICS channel partners that offer inperson and online classes worldwide, all based on the APICS Learning System The InstructorLed option features the same online Learning System tools that are in the SelfStudy optionAPICS Dictionary, 14th edition S&OP Processes Planning Objectives of S&OP ‐ S&OP supports and measures the progress of the entire organization in meeting the enterprise's business plan ‐ S&OP ensures that the strategic plans developed in the business plan are realisticDefinition 1)translates the strategic plan into production rates 2)continually updates the production, financial and sales plan 3)seeks input from various functions (ieengineering, customer service) 4)requires regular meetings with senior executives to resolve tradeoffs 5) checks availability of resources to validate the production plan

Sales Operations Planning S Op تخطيط العمليات والمبيعات Youtube

Apics Monadnock Chapter Webinar Fundamentals Of S Op Youtube

Answer APICS was originally an acronym for what was earlier known as American Production and Inventory Control Society Around 1990 it was renamed as (just) APICS Inc It is a non profit organization in US with headquarters in Chicago Originally there was just one certificate that APICSAdd all the actual (or

Apics Org

Sales And Operations Planning Pdf Forecasting Supply Chain Management

Scielo Br

Apics Org

Implementing An S Op System Here S How To Make Your Data Work For You Supply Chain Link Blog Arkieva

The Effect Of Sales And Operations Planning S Op On Supply Chain S Total Performance A Case Study In An Iranian Dairy Company Sciencedirect

What Is Supply Chain Management Scm

Apics Introduction To Sales And Operations Planning S Op Ppt Download

Apics Principles Of Operations Management Topic Outline Concepts And Applications Pdf Free Download

Supply Chain Management Wikipedia

Apics Pdm Big Data In Supply Chains Uses

Nexviewconsulting Com

The Lost Link To Make Strategy Work Sales Operations Planning S Op Strategok By Javier Gonzalez

Sales And Operations Planning A Business Practice To Align Supply Chains By Ijaems Research Journal Issuu

Calameo Apics Operations Management Body Of Knowledge Framework

Apics Introduction To S Op Handout Msol 5500 Financial Concepts Studocu

Scielo Brasil A Case Method For Sales And Operations Planning A Learning Experience From Germany A Case Method For Sales And Operations Planning A Learning Experience From Germany

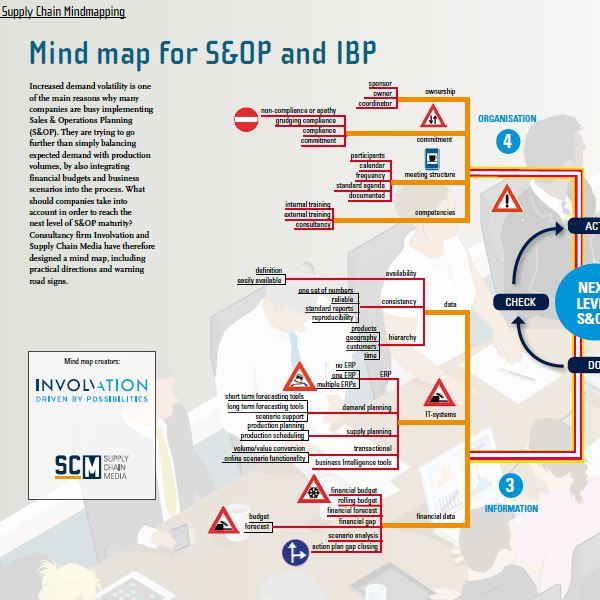

Mindmap For S Op And Ibp Supply Chain Movement

What Is S Op How S Op Works Demand Planning Com

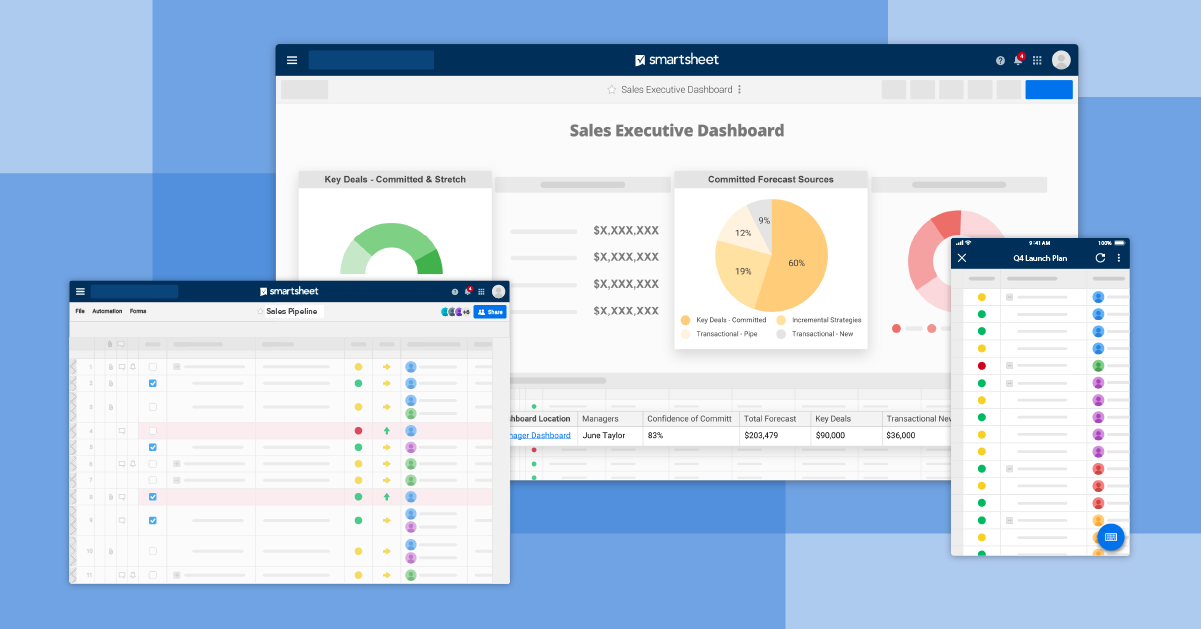

Sales And Operations Planning S Op 101 Smartsheet

Dspace Lib Cranfield Ac Uk

The Effect Of Sales And Operations Planning S Op On Supply Chain S Total Performance A Case Study In An Iranian Dairy Company Sciencedirect

Tandfonline Com

Sales And Operations Planning In Company Supply Chain Based On Heuristics And Data Warehousing Technology Pdf Free Download

Sales And Operations Planning Supply Chain Business Solutions

Sales And Operations Planning In Manufacturing Manage Collaboration Across The Entire Organization Tompkins Solutions

An S Op Must

Manufacturing Resources Planning Supply Chain Business Solutions

Apics To Update Industry Recognized Scor Model In Its th Year Supply Chain Management Review

Iopscience Iop Org

Ascm Org

A New Definition For Integrated Business Planning Supply Chain Trend

Apics Introduction To S Op Pdm Pptx Apics Introduction To Sales And Operations Planning S Op Apics And Proprietary Visual 1 Confidential Apics Course Hero

Scm Awareness S Op Process Planpotential

S Op What Is It And Why Should You Care Valve World

Sales And Operations Planning An Exploratory Study And Framework Emerald Insight

Apics S Op Performance Advancing Sales And Operations Planning In Supply Chain

Sales And Operations Planning S Op 101 Smartsheet

S Op Vs Ibp What Is The Difference Scmdojo

Iopscience Iop Org

Apics Introduction To Sales And Operations Planning S Op Ppt Download

Apics Introduction To Sales And Operations Planning S Op Ppt Download

The S Op And The 3 Different Levels Of General Planning Based On Apics Download Scientific Diagram

1

1

How Can Demand Management Drive Your Sales Operations Planning Moore

Scielo Brasil A Case Method For Sales And Operations Planning A Learning Experience From Germany A Case Method For Sales And Operations Planning A Learning Experience From Germany

S Op 101 For Manufacturing Executives Youtube

Mindmap For S Op And Ibp Supply Chain Movement

Scm Awareness S Op Process Planpotential

Educational Videos Ascm 19

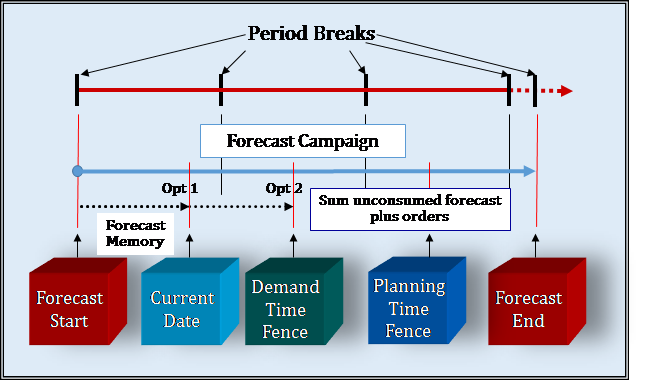

Managing The Demand Forecast Part 3 Apics Blog

S Op Process

Ascm Org

Scmchamp Blogspot Com

Apics S Op Performance Advancing Sales And Operations Planning In Supply Chain

The 5 Most Common Sales Operations Planning Mistakes And How To Avoid Them Supply Chain 24 7

The S Op And The 3 Different Levels Of General Planning Based On Apics Download Scientific Diagram

Principles Iscs Ltd

Smoother Execution Through S Op Supply Chain Management Review

Sciencedirect Com

S Op Process

Apics Principles Of Sales Operation Planning S Op Knowerx Top Level Partners Of Apics

Pdf Sales And Operations Planning A Comparison Between The Demand Driven And Traditional Approaches

Getting To Grips With Sales And Operational Planning Bloor Research

Apics Principles Sales Operation Planning S Op Educational Course Knowerx Top Level Partners Of Apics

5 Reasons Why Sales And Operations Planning Is Important Scmdojo

Apics Org

Apics Introduction To S Op Pdm Pptx Apics Introduction To Sales And Operations Planning S Op Apics And Proprietary Visual 1 Confidential Apics Course Hero

Ppt Apics Introduction To Sales And Operations Planning S Op Powerpoint Presentation Id

Apics Introduction To Sales And Operations Planning S Op Ppt Download

S Op A Vision For The Future The Expert Interview Series 7 Supply Chain Trend

Best Of The Best S Amp Op Conference Apics

Smoother Execution Through S Op Supply Chain Management Review

Ijaems Com

What Is Integrated Supply Chain Planning Logistics Viewpoints

1

Sales Operations Planning Two Decades Of Learning At Basf Ppt Video Online Download